Cyclonic Bag Filter

Cyclonic Bag Filter Specification

- Diameter

- 250 mm

- Resistance

- 1200 Pa

- Efficiency (%)

- 99%

- Type

- Cyclonic Bag Filter

- Material

- Polyester Fiber / Stainless Steel Housing

- Thickness

- 1.7 mm

- Thermal Shrinkage

- 1%

- Working Temperature

- Up to 240C

- Application

- Industrial Dust Collection

Cyclonic Bag Filter Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 400 Pieces units Per Month

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per buyers requirement packing available.

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, South America, Western Europe, Africa, Asia, Central America, North America

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About Cyclonic Bag Filter

As an ISO 9001:2008 certified company, we are engaged in manufacturing, exporting and supplying the best quality Cyclonic Bag Filter. Widely demanded in chemical, pharmaceutical, fertilizer and many other industries, this filter is used for filtering air and for keeping the surrounding free from impurities. Offered filter is manufactured under the direction of proficient experts using high grade raw materials with the help of ultra-modern technology at par with set industry standards. Moreover, clients can avail this Cyclonic Bag Filter from us as per their needs within the promised time frame.

Features:

-

Sturdiness

-

Robust construction

-

Precisely engineered

-

Long service life

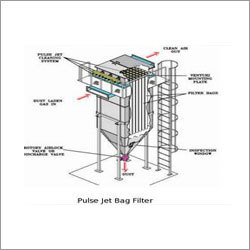

Advanced Dust Collection for Industrial Environments

Our Cyclonic Bag Filter leverages pulse jet cleaning and tangential air inlet technology to ensure consistent, efficient dust removal. The cyclonic action pre-separates heavy particles, thereby reducing filter load and extending bag life. Its corrosion-resistant finish ensures longevity, even in harsh industrial conditions, making maintenance straightforward and system efficiency consistently high.

Optimal Performance at High Temperatures

Designed to handle operating temperatures up to 240C, this filter features a polyester fiber filter media paired with a durable stainless steel housing. With minimal thermal shrinkage (1%), it delivers reliable filtration and mechanical integrity, even during high-temperature processes. This resilience makes it ideal for industries demanding resilient dust collection solutions.

FAQs of Cyclonic Bag Filter:

Q: How does the pulse jet cleaning method in this Cyclonic Bag Filter work?

A: The pulse jet cleaning method periodically releases compressed air in short bursts through the filter bags, dislodging accumulated dust. This maintains filter permeability and efficiency without the need for manual cleaning, extending the lifespan of the filter bags.Q: What industrial applications are best suited for this Cyclonic Bag Filter?

A: This filter is ideal for a range of industrial dust collection needs, particularly in environments with high dust loads and elevated temperaturessuch as metal processing, cement, chemical manufacturing, and power plants.Q: When should the filter bags and rotary airlock valve be inspected or serviced?

A: Regular inspections are recommended based on operating hours and dust load. Typically, filter bags and the rotary airlock valve should be checked every 36 months to ensure optimal performance and to prevent unexpected downtime.Q: Where can the Cyclonic Bag Filter be installedvertically or horizontally?

A: This filter is designed for flexible installation and can be mounted either vertically or horizontally, making it adaptable to various plant layouts and available spaces.Q: What advantages does the tangential air inlet provide in dust collection?

A: The tangential air inlet introduces dust-laden air at an angle, producing a cyclonic effect that helps separate larger particles before they reach the filter bags. This reduces wear, lowers pressure drop, and increases overall filter efficiency.Q: How is dust safely discharged from the housing?

A: Dust is collected in a hopper and discharged using a rotary airlock valve. This mechanism ensures airtight transfer of dust, preventing air leakage and facilitating safe, continuous disposal without system interruption.Q: What benefits does the corrosion-resistant paint and stainless steel housing offer?

A: The corrosion-resistant paint and stainless steel construction provide excellent durability against harsh chemicals and environmental factors, ensuring a long service life and reliable performance even in aggressive industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Filter Category

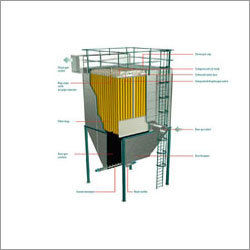

Automatic Pulse Jet Bag Filter

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel / Stainless Steel / GI (customized options available)

Thermal Shrinkage : 1%

Efficiency (%) : 99% and above

Type : Other, Automatic Pulse Jet Bag Filter

Application : Industrial dust collection, cement plants, power plants, steel mills, chemical processing, food industries

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS