Automatic Pulse Jet Bag Filter

Automatic Pulse Jet Bag Filter Specification

- Diameter

- 130 mm / 160 mm / 180 mm (customizable)

- Efficiency (%)

- 99% and above

- Type

- Automatic Pulse Jet Bag Filter

- Material

- Mild Steel / Stainless Steel / GI (customized options available)

- Thermal Shrinkage

- 1%

- Working Temperature

- Ambient to 250C

- Application

- Industrial dust collection, cement plants, power plants, steel mills, chemical processing, food industries

Automatic Pulse Jet Bag Filter Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque, Cash in Advance (CID)

- Supply Ability

- 400 Pieces units Per Month

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per buyers requirement packing available.

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About Automatic Pulse Jet Bag Filter

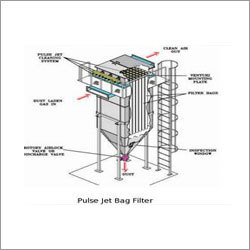

As a quality certified entity in this domain, we are offering a wide gamut of premium quality Automatic Pulse Jet Bag Filter. The provided filter is manufactured using the optimum quality components and ultra-modern technology under the supervision of our knowledgeable professionals. Available in different technical specifications, our offered filter is extensively used for cleaning the air. Moreover, the provided Automatic Pulse Jet Bag Filter is tested against diverse parameters by our quality auditors.

Features:

-

Suitable for light and fine dust

-

Maximum cleaning efficiency

-

Automatic operation

-

Rugged design

Superior Dust Collection Efficiency

Engineered for industrial use, the Pulse Jet Bag Filter maintains exceptional dust removal efficiency, achieving up to 99% and above. Its advanced pulse jet cleaning mechanism ensures consistent performance even in challenging environments with high dust loads, reducing emissions to 30 mg/Nm3 and promoting workplace safety.

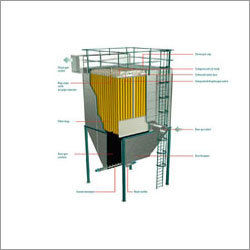

Customizable Design for Versatility

With options for 10 to 500 bags, multiple bag lengths, and diameter choices, this filtration system is tailored to suit a wide variety of processing requirements. Material and frame customization allow compatibility with high-temperature and corrosive environments, ideal for industries ranging from cement and steel to food and chemical processing.

Automated Operation with Minimal Maintenance

The integrated PLC-based automatic control system streamlines filter operation, optimizing cleaning cycles and reducing manual intervention. Maintenance is simplified through top or side entry, which enables quick bag changes and inspections, keeping downtime to a minimum and ensuring sustained filtration efficiency.

FAQs of Automatic Pulse Jet Bag Filter:

Q: How does the compressed air pulse jet cleaning method work in this bag filter?

A: The compressed air pulse jet cleaning process involves bursts of compressed air directed into the bags, dislodging accumulated dust from the filter surface. This ensures continuous filtration efficiency and prevents clogging, maintaining low pressure drops and prolonging bag life.Q: What industries or applications are best suited for this automatic pulse jet bag filter?

A: This bag filter is ideally suited for industrial dust collection in sectors such as cement plants, power plants, steel mills, chemical processing facilities, and food industries. Its robust construction and high efficiency make it suitable for both heavy and fine dust applications.Q: When is maintenance required, and how can access be achieved?

A: Regular inspections based on process dust levels are recommended. The filter is designed for easy maintenance access via top or side entry points (as per design), enabling convenient bag replacement or cleaning without extensive downtime.Q: Where can this bag filter be installed within an industrial facility?

A: The unit can be installed at key dust-generating points throughout an industrial facility, such as material transfer locations, processing lines, or exhaust stacks. Installation design is flexible to suit site requirements and available space.Q: What benefits does the automatic PLC-based control system provide?

A: The PLC-based automatic control system optimizes filter cleaning cycles, manages differential pressure, and ensures reliable operation with minimal manual intervention. This results in energy savings, reduced maintenance, and consistent emission control performance.Q: How is the filter customized for different dust loads or temperature requirements?

A: Customization options include varying the number and length of filter bags, selecting diameter sizes, and choosing materials like mild steel, stainless steel, or GI for specific dust, temperature, or corrosion resistance requirements.Q: What is the typical process flow when using this automatic pulse jet bag filter in operation?

A: Dust-laden air enters the filter housing, passes through the filter bags where dust is captured, and clean air exits the system. Periodic compressed air pulses clean the bags, while collected dust is released to a hopper for removal, maintaining continuous and efficient filtration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Filter Category

Cyclonic Bag Filter

Minimum Order Quantity : 1 Piece

Application : Industrial Dust Collection

Type : Other, Cyclonic Bag Filter

Resistance : 1200 Pa

Working Temperature : Up to 240C

Material : Other, Polyester Fiber / Stainless Steel Housing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS